Client:

The Earl of Cromartie

Architect:

LDN Architects

Background Information

Harper & Allan Masonry Ltd were awarded the contract for repair works to the home of the Clan MacKenzie in November 2015 working alongside LDN Architects in Forres.

The castle is believed to have been built on the site of a very ancient Pictish fort from before the 12th century. The current castle is the result of work carried out in the early 17th century by Sir Roderick Mackenzie, the ancestor of the Earl of Cromartie. The castle has remained the seat of the Earls of Cromartie ever since.

Scope of Works

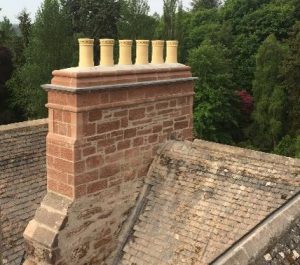

Works were concentrated on 3 of the castle chimneys where previously inappropriate materials had been used in the past causing significant water retention on the already soft friable sandstone.

Investigation

To determine the current condition of the stonework, all cement repairs were removed using hand held masonry tools and areas opened up to discover the current details of the leadworks. When opened up it was discovered that the building fabric was in places built out with 50mm of dense cement render and the fabric saturated and poor lead detailing had led to increased water ingress

Stone Sourcing & Matching Original

St bees Sandstone was chosen as this was the closest match to the original stone from samples obtained from around the country. Once the stone type had been confirmed the sizes previously taken were confirmed to the quarry for manufacture and the chimneys were then wrapped up with tarpaulins from the highland winter.

Stone Dressing

Templates were taken of the original profiles and texture finishes and work began with the stone dressing in our yard in Keith. In total 7m3 was cut to various profiles then transported to site

Building of Chimney 5

Stone was then carefully transported to site and laid out in courses ready for building. Each chimney was then built and then pointed with traditional lime mortar.

Building of Chimney 4

Joinery

Due to poor lead detailing we discovered that sections of the roof were rotten and required replacement prior to installation of new lead details. Alan Hardie Joinery were contacted to renew these sections to allow the roof to be resealed

Lead Detailing

When the roof was replaced in 1990 the lead detailing used was not sufficient to seal the junction between the chimney and the roof. Harper & Allan Masonry worked closely with Firth Plumbing and LDN Architects to ensure all points were sealed where they met. New code 6 lead was installed behind the turrets and along ensuring a raggle was cut and the new lead work sealed properly